पीतल बेल्ट उत्पादन प्रक्रिया और रखरखाव विधि बेल्ट

biz pirinç Kemer kilidini muhafaza edilmiştir, öncelikle pabuçları kaldırmak ve temizlik önlemek için her iki tarafta pirinç kemeri tokası ayrılmalıdır. biz pirinç kemer de tokası korursak, pratik süresi daha uzun olacak ve biz pirinç kemer tokası seçerken kaliteyi seçmek hatırlamalıyız. Şimdi piyasada pirinç kemer tokası ürünleri de karşılaştırılmaktadır. Daha. Yukarıda, herkesin pirinç kemer üretim süreci ve bakım yöntemlerini tokası bilir umut pirinç kemer tokası üretim süreci ve bakım yöntemlerinin tanıtımı ile ilgili olup, herkese yararlıdır.? How to maintain the brass belt buckle? The following small series will explain the production process and maintenance methods of the brass belt buckle for everyone, I hope to help everyone.

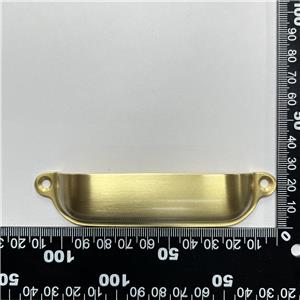

Brass belt buckle production process

The brass belt buckle production process is similar to other belt buckles. Firstly, the design drawings are confirmed to the customer, and then the mold is opened, the mold is opened, the copper embryo is cut, the wire is cut, and the spark is sparked.

After the mold is made, put the mold on the die casting machine to debug, and after the machine is stable, it will be normal beer. After the beer comes out, it is necessary to scrape the front and press the nail (the monk head). The nail is also very particular. The length of the nail is designed according to the thickness of the belt. Otherwise, there is no way to change it. How big the nail is, according to the size of the belt hole, sanding, polishing, grinding out and passing the quality inspection, you can enter the electroplating workshop, after the plating, you must pass the truss, when you pass the truss, you must wait for the brass belt. After the buckle is completely dried, the temperature can be cooled down before the packaging can begin.

Brass belt buckle maintenance method

1. When the brass belt buckle produces acid odor, use a soft toothbrush to dilute some of the fragrant soap to quickly wash the dirt. Rinse quickly with water, and squeeze the soap with a pinch and release method. The process is 15 The comparison is good in seconds; in addition, the brass belt buckle maintenance is completed by natural air drying or by using a hair dryer at a distance of 15 cm (free of brass belt buckle burnt deformation).

2. brass belt buckle accidentally wet or rain, should be removed as soon as possible, immediately dry with a dry cloth and wring out, can continue to wear; because the human body has body temperature, if you want to collect must be naturally dried or in The brass belt buckle is coated with leather oil, which has a protective effect on the brass belt buckle and better maintenance of the brass belt buckle.

When we are maintaining the brass belt buckle, we should first remove the lugs and separate the brass belt buckles on both sides to avoid cleaning. If we maintain the brass belt buckle well, the practical time will be longer, and we should remember to choose the quality when choosing the brass belt buckle. Now the products of the brass belt buckle on the market are also compared. More.

The above is about the introduction of the brass belt buckle production process and maintenance methods, I hope everyone knows the brass belt buckle production process and maintenance methods, it is helpful to everyone.